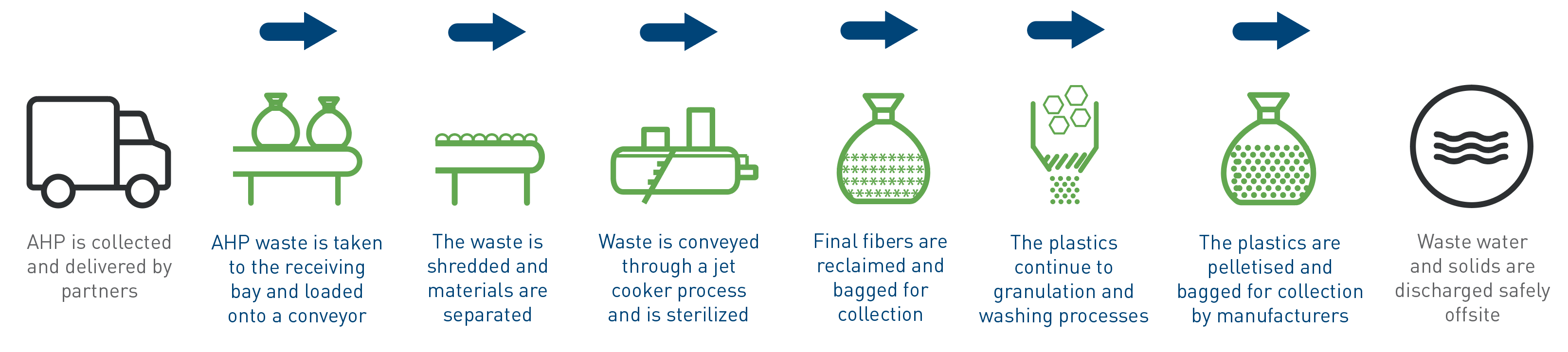

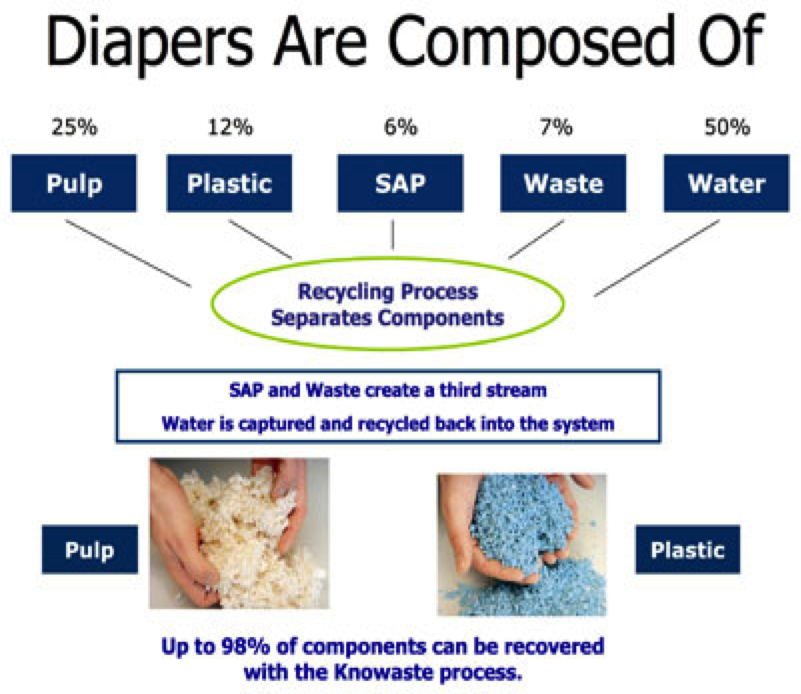

The Knowaste Recycling ProcessThe Knowaste process is simple and effective. The Knowaste process sanitizes the diaper material and uses a water and mechanical system to separate the individual components so the wood pulp and plastic can be recycled. Human waste is separated and treated through the local sewage system. Up to 98 per cent of a used disposable diaper or incontinence product can thus be removed from the waste stream. High-quality wood pulp and plastic are now available for recycling.

Recycling Offtake: Marketable Byproducts of our ProcessExtensive research at Knowaste’s development plant in West Bromwich allowed the Company to identify a range of uses for the high quality recycled plastic and fiber that is produced. Knowaste has secured Letters of Intent from strategic partners for the long term contractual sale of its high quality recycled plastic and fiber.

Plastics

4,000 tpa (11% of plant capacity) per plant into plastic pellets for the injection molding market in a range of recycled products including timber replacement, molded items, diaper and hygiene bins. The current price achievable for these pellets is c.$350 per ton. Knowaste intends to be the main supplier of recycled plastic for the manufacture of the containers that collect the AHPs for both the commercial and local authority sectors. Fiber 8,000 tpa (22% of plant capacity) per plant providing a range of recycled products including cardboard packaging, concrete and tarmac additive, bricks, insulation materials, pet bedding and litter. Current price for this material is c.$300 per ton. The recycled fiber will be utilized in the production of pet litter/bedding which will be produced and bagged on site for onward transportation to the retailer/wholesaler. |

Knowaste Technology in ActionWatch this short film outlining the key process stages of a Knowaste AHP recycling plant and the benefits to your customers and recycling sector.

Where are diapers going for disposal in your community?

|

|

Vertical Divider

|

Contact Roy Brown, President & CEO

|